Production Process

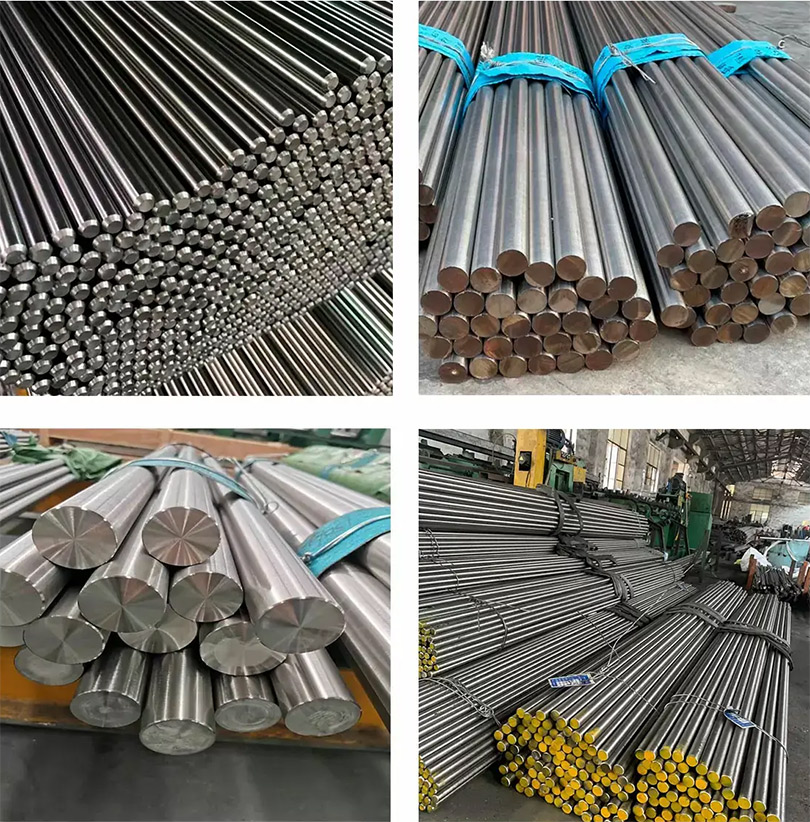

The following steps make up the production process: Raw materials (C, Fe, Ni, Mn, Cr, and Cu) are smelted into ingots by AOD finery, hot rolled into a black surface, pickled in acid liquid, polished automatically by machine, and then cut into pieces.

ASTM A276, A484, A564, A581, A582, EN 10272, JIS4303, JIS G 431, JIS G 4311, and JIS G 4318 are some applicable standards.

Product Dimensions

Hot-rolled: 5.5 to 110mm

Cold-drawn : 2 to 50mm

Forged Form : 110 to 500mm in

Standard Length : 1000 to 6000 mm is the

Tolerance : H9&H11

Product Features

● Cold-rolled product shine with a nice appearance

● Very strong at high temperatures

● After weakly magnetic processing, nice work-hardening

● Solution in a non-magnetic condition

Application

Suitable for uses in architecture, building, and other fields

Applications include the construction industry, the shipbuilding industry, and outdoor advertising billboards.Bus interior, exterior, packing, structure, and springs metal electroplating, handrails etc.

Standard of

The composition of 304 steel, especially the nickel (Ni) and chromium (Cr) levels, play a vital role in determining its corrosion resistance and overall value. Although Ni and Cr are the most important elements in 304 steel, other elements may be included. Product standards outline specific requirements for Type 304 steel and vary depending on the shape of the stainless steel. Generally, if the Ni content is greater than 8% and the Cr content is greater than 18%, it is considered to be 304 steel, often called 18/8 stainless steel. These specifications are recognized by the industry and defined in related product standards.