Chemical Composition

| Grade | C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr |

| 201 | 0.15 | 1 | 5.50-7.50 | 0.5 | 0.03 | 3.50-5.50 | 16.00-18.00 |

| 202 | 0.15 | 1 | 7.50-10.00 | 0.5 | 0.03 | 4.00-6.00 | 17.00-19.00 |

| 304 | 0.08 | 1 | 2 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

| 304L | 0.03 | 1 | 2 | 0.045 | 0.03 | 8.00-12.00 | 18.00-20.00 |

| 309 | 0.2 | 1 | 2 | 0.04 | 0.03 | 12.00-15.00 | 22.00-24.00 |

| 309S | 0.08 | 1 | 2 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

| 310 | 0.25 | 1 | 2 | 0.04 | 0.03 | 19.00-22.00 | 24.00-26.00 |

| 310S | 0.08 | 1 | 2 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

| 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316Ti | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 410 | 0.15 | 1 | 1 | 0.04 | 0.03 | 0.6 | 11.50-13.50 |

| 430 | 0.12 | 0.12 | 1 | 0.04 | 0.03 | 0.6 | 16.00-18.00 |

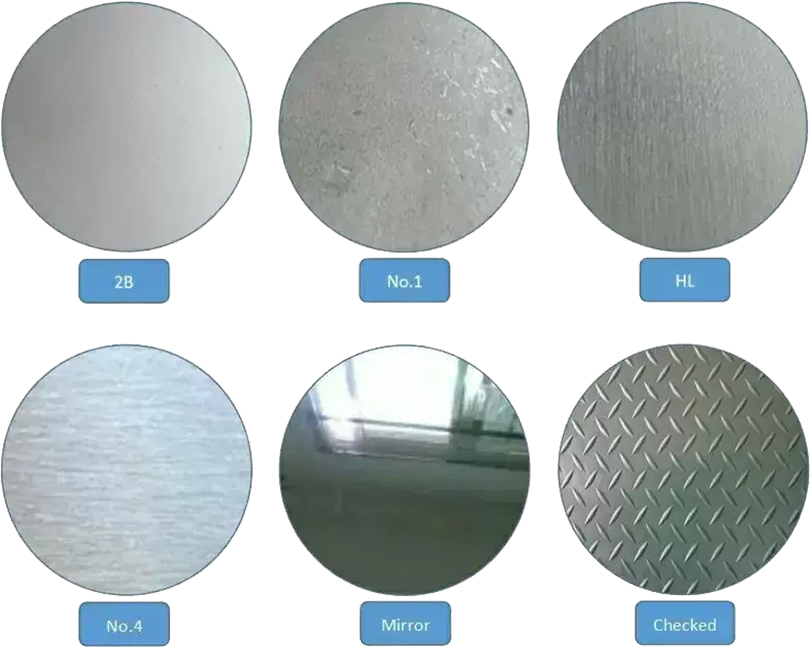

Surface Finish of Stainless Steel Coil

| Surface Finish | Definition | Application |

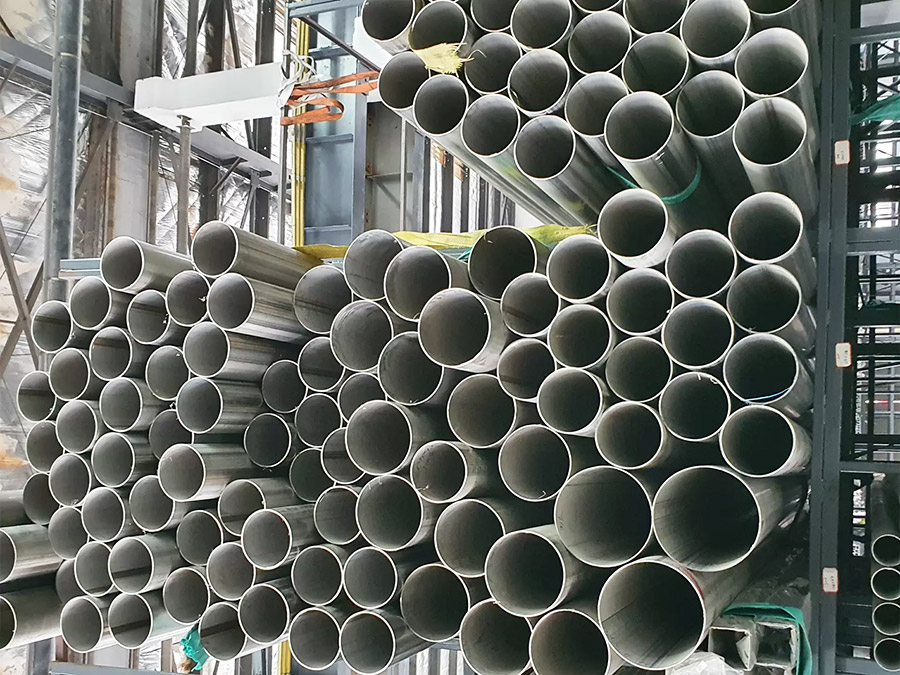

| No.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| No.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Electric equipment, Building construction. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| BA/8K Mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building const |

Knowledge of Stainless Steel

● 304 Stainless Steel

304 stainless steel is a highly versatile material commonly used in the manufacture of equipment and parts that require excellent overall properties, including corrosion resistance and formability. To ensure its inherent corrosion resistance, stainless steel must contain at least 18% chromium and 8% nickel.

Standard of

The composition of 304 steel plays a vital role in determining its corrosion resistance and value. Although nickel (Ni) and chromium (Cr) are the main elements, other components may also be involved. The product standard specifies the specific requirements for 304 steel. It is generally understood in the industry that if the Ni content exceeds 8% and the Cr content exceeds 18%, it can be classified as 304 steel. That's why it's often called 18/8 stainless steel. It should be noted that there are clear regulations in the relevant product standards of 304 steel, and these regulations may vary according to the shape and form of stainless steel.