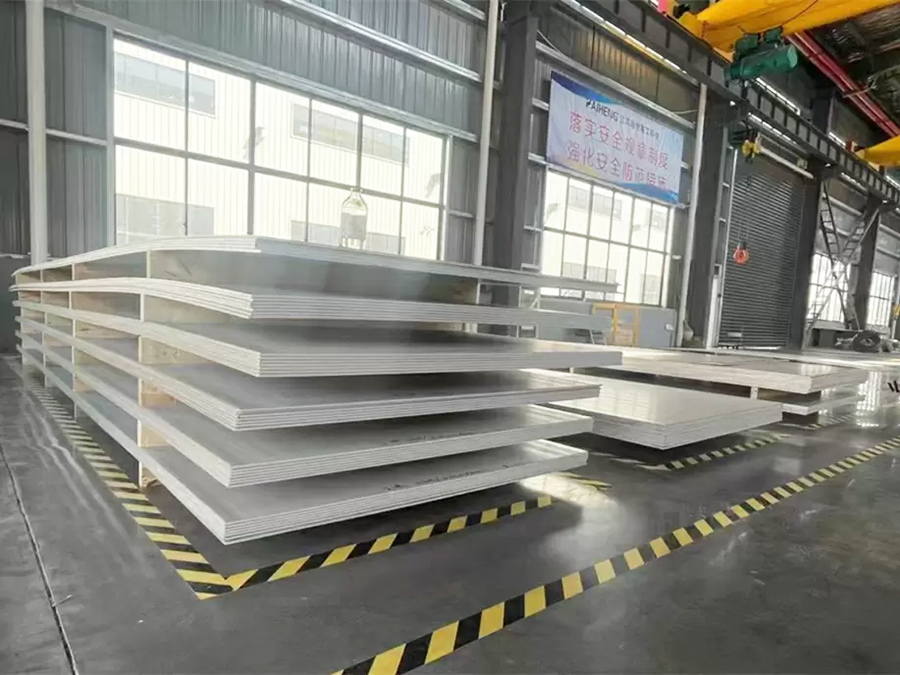

Product Description

Our exceptional product - 316 Stainless Steel. Known for its exceptional quality, this stainless steel variant has a composition of 18% chromium, 12% nickel and 2.5% molybdenum. It is precisely because of the addition of molybdenum that the steel exhibits remarkable corrosion resistance, excellent atmospheric corrosion resistance and excellent high temperature strength. This makes it suitable for use even in the harshest conditions.

Chemical Composition

| Grade | C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr |

| 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316Ti | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

Product Features

Excellent Work Hardening Ability : This means it resists deformation and maintains its structural integrity even under enormous pressure. Additionally, this steel variant is non-magnetic, making it ideal for applications where magnetism may interfere with desired functionality.

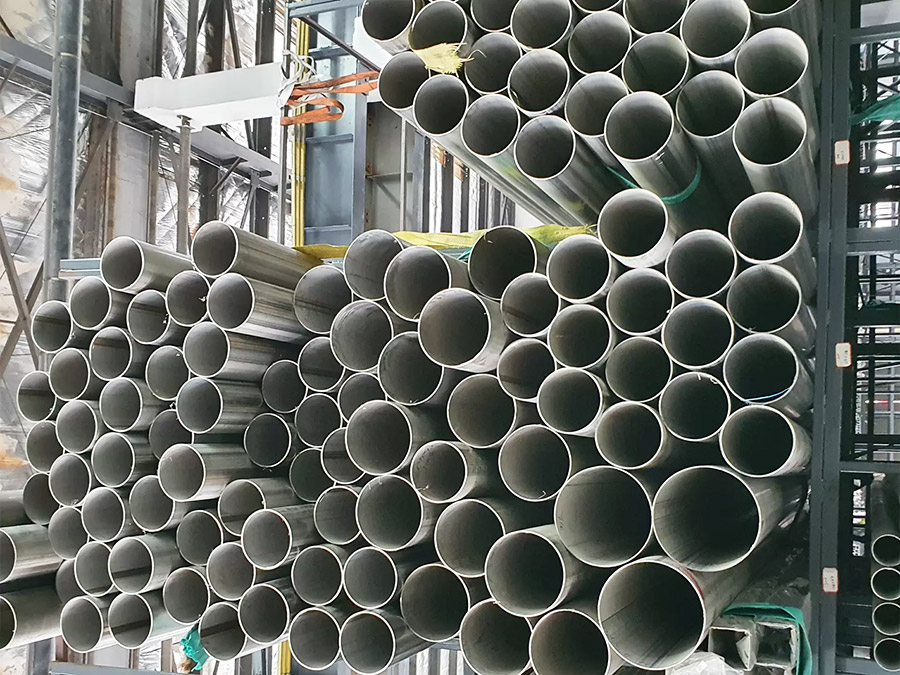

The versatility : It has a wide range of uses in various industries and applications. In the marine industry, this steel is the first choice for seawater equipment due to its excellent saltwater corrosion resistance. Its chemical resistance makes it an excellent choice for production equipment in the chemical, dye and paper industries, which are frequently exposed to aggressive substances.

Corrosion Resistant : Its corrosion-resistant properties make it an excellent material for coastal installations that are often exposed to salt water and moisture. Due to its exceptional strength and durability it is also used in the production of ropes, CD rods, bolts and nuts.

Application

Whether it's seawater equipment, chemicals, dyes, paper, or any other industry that requires a strong, corrosion-resistant material, our 316 stainless steel is the ideal choice. Trust the quality and functionality of our product and let it exceed your expectations.